METAL FEELING

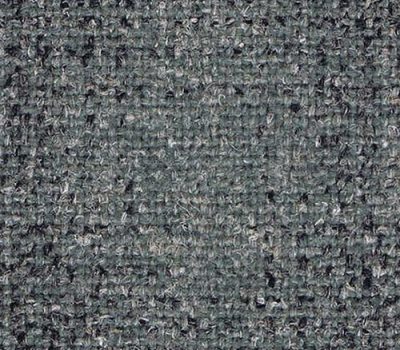

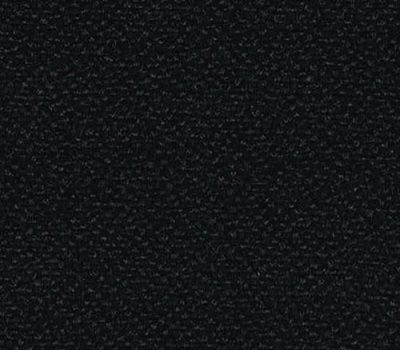

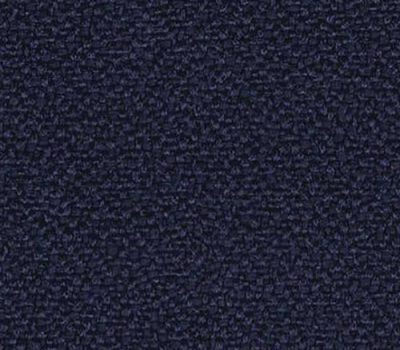

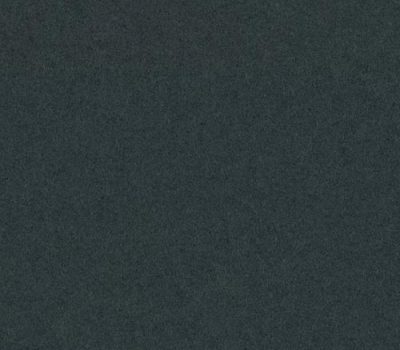

A1 – INDUSTRIAL BLACK

Refined and resistant handmade finishing for indoors and outdoors. It is manually coated by our our craftsmen, able to give a brilliant and soft appearance to surfaces, to change its color with the light’s variations, always pleasant for sight and tact. Ideal for metal and steel, thus able to grant an excellent result also on plastic.

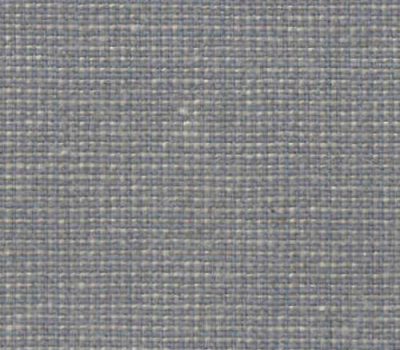

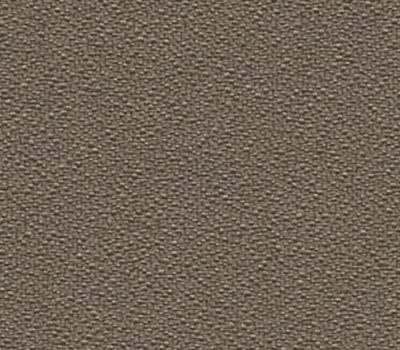

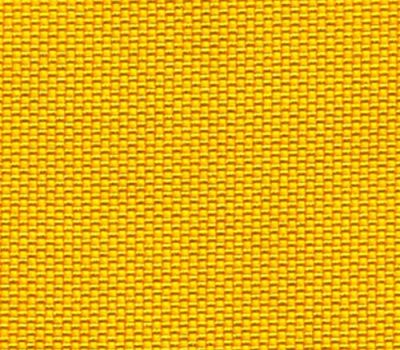

F1 – TARNISHED BRASS

Charming and resistant artisanal finishing for indoors and outdoors, on metal/stainless steel and plastic materials. The manual coating is able to recreate the glamorous effect of antiqued brass, adding a story to the furnished spaces. There are various color effects provided by this type of coating, with the yellow background enhanced by green reflections recalling the natural oxidation of brass. This finish has got the advantage of not being subjected to color variations with time, also when used in outdoors.

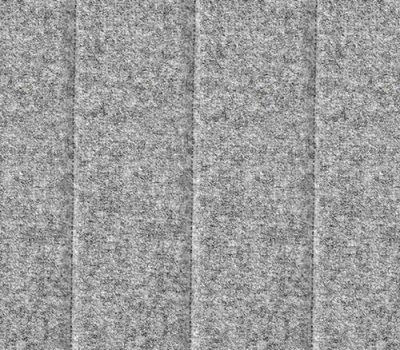

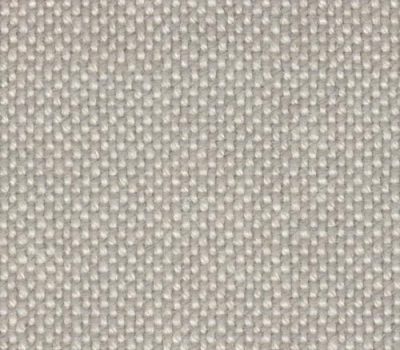

F2 – BRASS BRISTLE

Sophisticated finishing, realized piece by piece. It recalls the effect of oxidated and brushed brass. It consists of the manual finishing of metal/stainless steel and plastic materials, carried out in several phases. After the first coating, which creates the brass oxidation effect, color is pulled manually to recreate the texture of real brush strokes. At the end of the process, one more layer of transparent coating is added to protect the chromatic effects and make it particularly suitable for indoors and outdoors. Being a manual processing, it may be subjected to variations in tone and homogeneity.

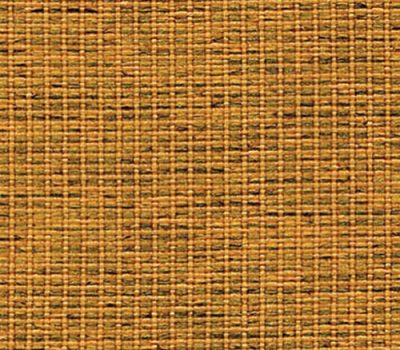

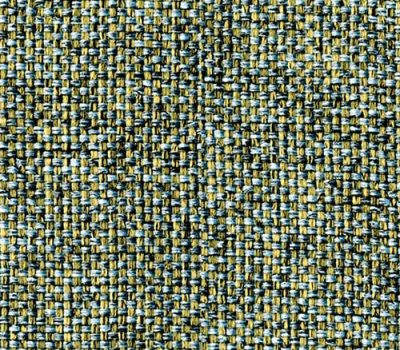

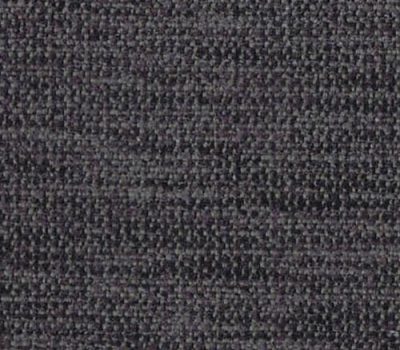

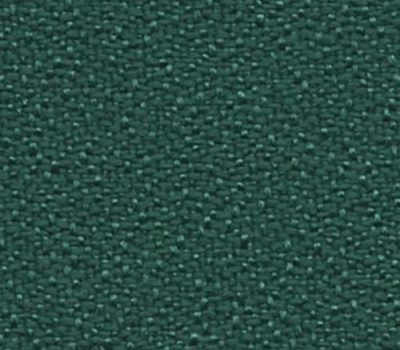

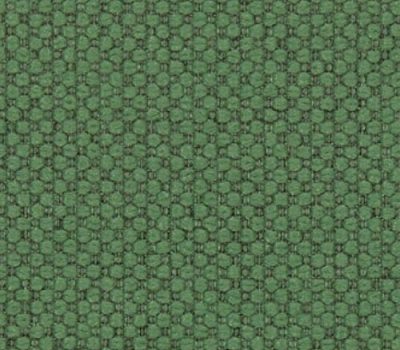

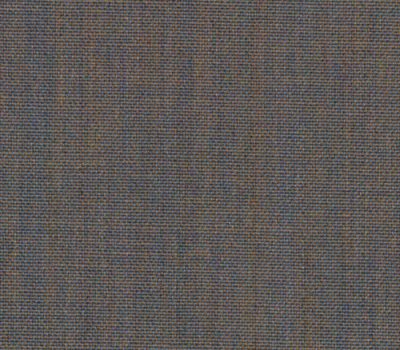

B1 – WOVEN GREEN

This elegant artesanal finishing recalls the weft threads of Italian fabrics. It is obtained through a first manual coating of the green background, with yellow reflections recalling the natural oxidation of the material. Afterwards the paint is pulled manually, with a scratched effect reminding of the intertwined threads of fabrics. At the end of the process, one more layer of transparent coating is added to protect the chromatic effects and make it particularly suitable for indoors and outdoors. This finishing is available on metal / stainless steel and plastic materials. Being a manual processing, it may be subjected to variations in tone and homogeneity.

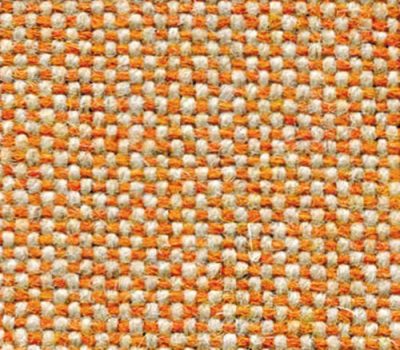

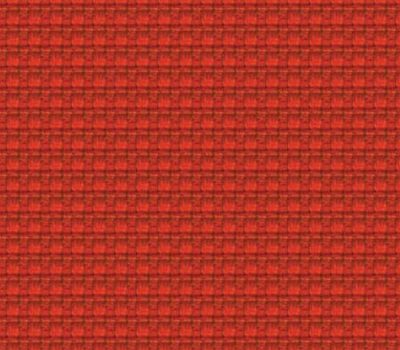

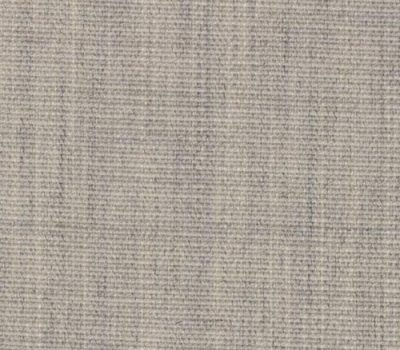

C1 – WOVEN COPPER

An amazing version of oxidated copper, with reflections and streaks that recall the texture of a metallic fabric. This high-end finishing is handmade, suitable for metal / stainless steel and plastic materials, on indoors and outdoors. The first layer of paint creates a copper background, with dark reflections to recall the oxidation of the material. Afterwards paint is pulled manually, giving a streaked effect similar to weft threads. At the end of the process, one more layer of protecting transparent coating is added. Being a manual processing, it may be subjected to variations in tone and homogeneity.

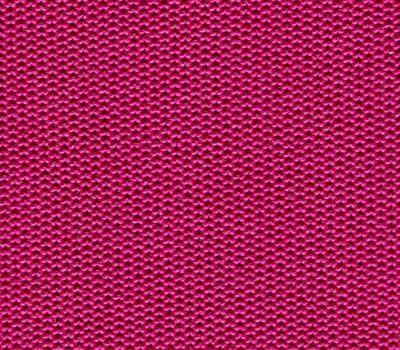

POWDER COATING

This kind of coating happens through anlectrostatic process, undertaken in different phases, at the end of which the object is placed on a specific oven at an average of 180°. Here the powder at first melts and then polymerizes, covering the object in a tiny layer of coating, yet homogenous and resistant. Suitable for indoor and outdoor on materials as metal/steel and plastic.

MASS COLOR FOR PLASTIC INJECTION

The most common process for mass production of plastic objects is injection molding. It is obtained thorugh special presses melting the plastic granules and injecting them at high speed and pressure into the molds, where the polymer, cooling, takes on the expected shape. In this phase of the process, it is possible to add RAL coloring (mass color), by adding a specific dye to the polymer, called masterbatch or master, which is completely and homogeneously deposited on the product.

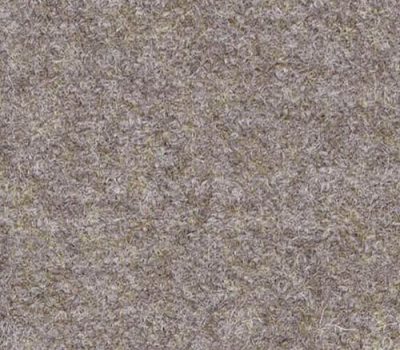

POST-INDUSTRIAL PLASTIC COLORS

The series production of objects in post-industrial plastic is carried out with the classic technique of injection molding. Instead of the common polymers, plastic granules derived from industrial production processes are used. Unlike the post consumer recycled plastic, the one coming from industrial processes offers better mechanical performaces and a better color tone. The material obtained through this process is more innovative and sustainable and it is available in an unique range of color options with a soft shade, which symbolizes its green approach.